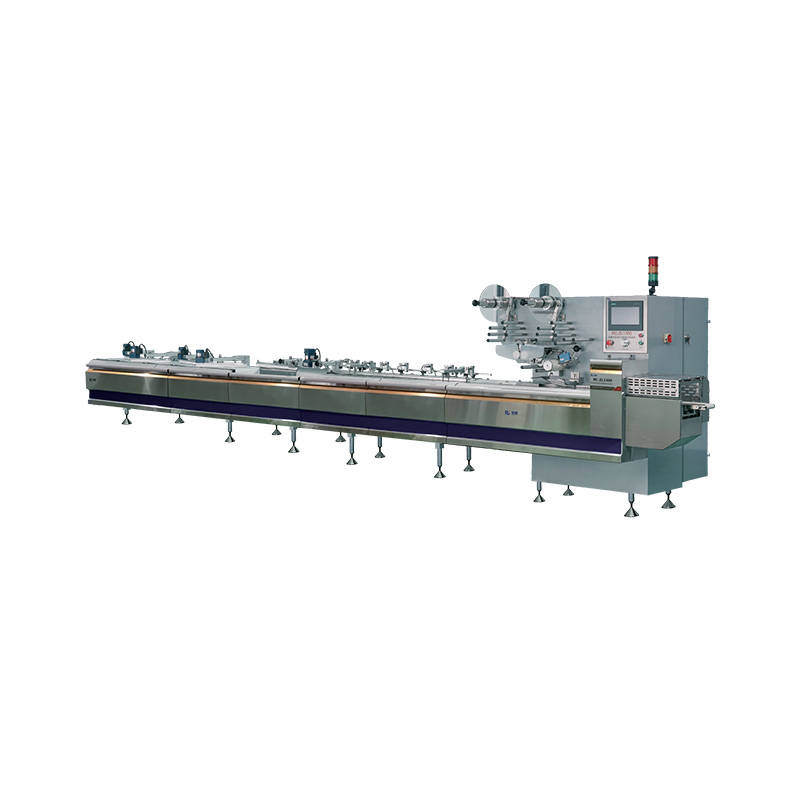

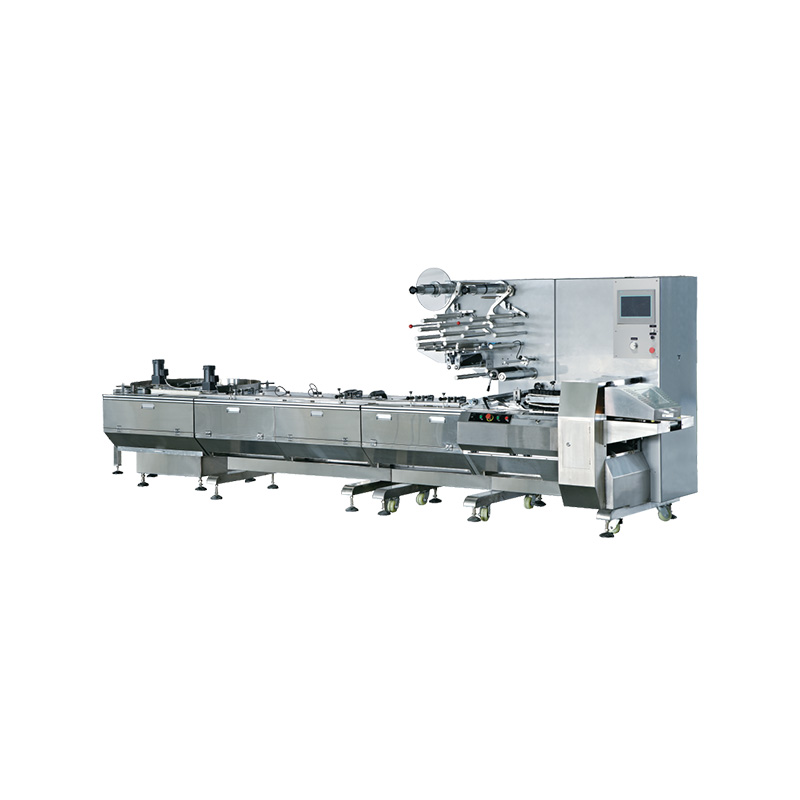

The WZ-WL100 Fully Automatic Multi-Functional Vertical Intelligent Ingredient Excavator represents the pinnacle of innovation in ingredient handling and excavation systems for high-volume food and pharmaceutical production lines. With its automated features and high-capacity design, it streamlines the process of transporting and excavating dry and semi-dry materials, ensuring enhanced efficiency, reliability, and precision across various manufacturing environments.

This state-of-the-art excavator is capable of handling a wide range of materials, from powders and granules to more complex ingredient types. Engineered for flexibility, the WZ-WL100 supports capacities ranging from 50KG/h to 3000KG/h, making it suitable for both small and large-scale production needs. With its cutting-edge technology, the system significantly reduces the need for manual labor, improves production efficiency, and guarantees uniform handling of ingredients.

Key Features and Advantages:

1. Optimized High-Capacity Performance

Wide Capacity Range: With an adaptable capacity of 50-3000KG/h, the WZ-WL100 can accommodate varying production volumes, making it ideal for both small and large operations. Whether your facility handles low-volume artisan production or high-volume industrial manufacturing, this system can meet your needs.

Efficient Ingredient Handling: The automated excavation process reduces material loss and enhances throughput, contributing to a more streamlined and productive workflow.

2. Powerful and Reliable Operation

2.75KW Motor: Equipped with a 2.75KW motor, the WZ-WL100 provides consistent and reliable power for demanding applications. The motor ensures smooth operation even during high-load tasks, promoting long-lasting durability and reducing the need for frequent maintenance.

Stable and Continuous Operation: Engineered to run continuously without overheating, the WZ-WL100 ensures uninterrupted performance across extended production cycles.

3. Ultra-Low Noise Operation

Quiet Performance (<10 dB): Designed for low-noise environments, the WZ-WL100 operates at a noise level of ≤10 dB, making it ideal for facilities where noise reduction is essential. This feature enhances the working environment for operators, reduces sound pollution, and helps meet regulatory noise standards.

4. Space-Efficient Design

Compact Machine Dimensions (1500×1800mm): Despite its high-capacity performance, the WZ-WL100 is designed to be compact and space-efficient. Its small footprint ensures it can be seamlessly integrated into existing production lines without taking up valuable floor space, making it ideal for facilities with limited room.

Optimal Working Stroke (2.41.83.7m): The excavator's vertical working stroke provides a precise and controlled method for material excavation, ensuring maximum efficiency while maintaining a clean and organized production area.

5. Fully Automated Functionality

Automatic Ingredient Excavation: The WZ-WL100 eliminates the need for manual ingredient handling. Its fully automated system ensures that ingredients are excavated with precision and consistency, reducing human error and improving product quality.

Enhanced Production Efficiency: By automating the excavation process, the WZ-WL100 increases overall production efficiency, ensuring higher throughput and reducing labor costs. Operators can focus on more critical tasks while the system handles ingredient excavation seamlessly.

6. Robust Construction and Easy Integration

Durable Construction: Built with high-quality materials, the WZ-WL100 is designed for longevity and durability. Its robust construction ensures that it withstands the rigors of continuous industrial use, providing a long service life and minimizing downtime.

Seamless Production Line Integration: The system is easy to integrate into existing production lines, ensuring minimal disruption during installation. Its intelligent design allows for a smooth connection with other machinery, making it an essential part of any automated production environment.

Applications:

The WZ-WL100 is designed for industries that require high-efficiency material handling and ingredient excavation, including:

Food Processing: Ideal for bulk handling of powders, granules, and semi-dry ingredients like flour, sugar, spices, and other food additives.

Confectionery Manufacturing: Perfect for efficiently excavating and handling ingredients such as milk powder, cocoa powder, and chocolate mix for confectionery products.

Pharmaceutical Production: Ensures accurate handling and transportation of powdered ingredients in the pharmaceutical industry, improving product quality and compliance.

Chemical Manufacturing: Can be adapted for the excavation and transport of various chemicals and additives in large-scale production environments.

Why Choose the WZ-WL100?

Enhanced Efficiency: Fully automated operations result in reduced downtime and optimized throughput.

Noise Reduction: Ultra-low noise operation makes it suitable for noise-sensitive environments.

Versatility: Capable of handling a wide range of materials, making it a valuable asset in any industrial food, pharmaceutical, or chemical production facility.

Durable & Low Maintenance: Built to last with robust construction, minimizing the need for maintenance and extending the lifespan of your equipment.

English

English