Product Search

Language

Exit Menu

Industry News

Home / News / Industry News / What to Consider When Selecting Gummy Packaging Equipment for Your Production Line

Author: RONGCHUANG

Date: 2024-10-29

What to Consider When Selecting Gummy Packaging Equipment for Your Production Line

When it comes to the production of gummy candies, effective packaging is crucial for maintaining freshness, ensuring quality, and attracting consumers. The right gummy packaging equipment can streamline the packaging process, enhance productivity, and ultimately impact a brand’s success in a competitive market.

Understanding Your Product Needs

It’s essential to understand the specific requirements of your gummy products. Gummy candies come in various shapes, sizes, and formulations, and each type may require different packaging solutions. For instance, some gummies are coated with sugar or sour powders, which may affect the type of packaging material used. Gummy packaging equipment should be tailored to handle these unique characteristics effectively.

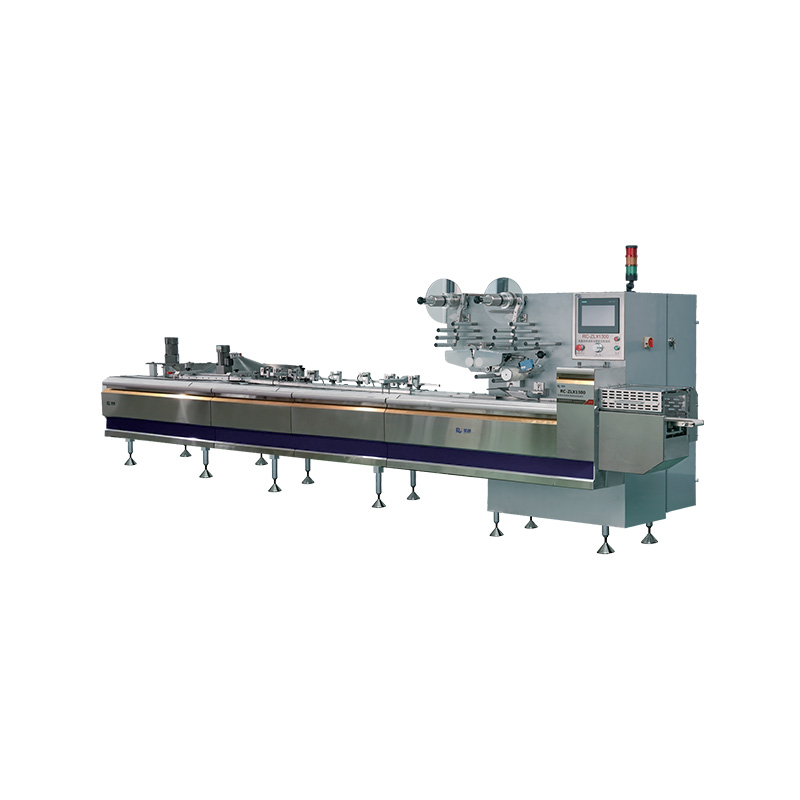

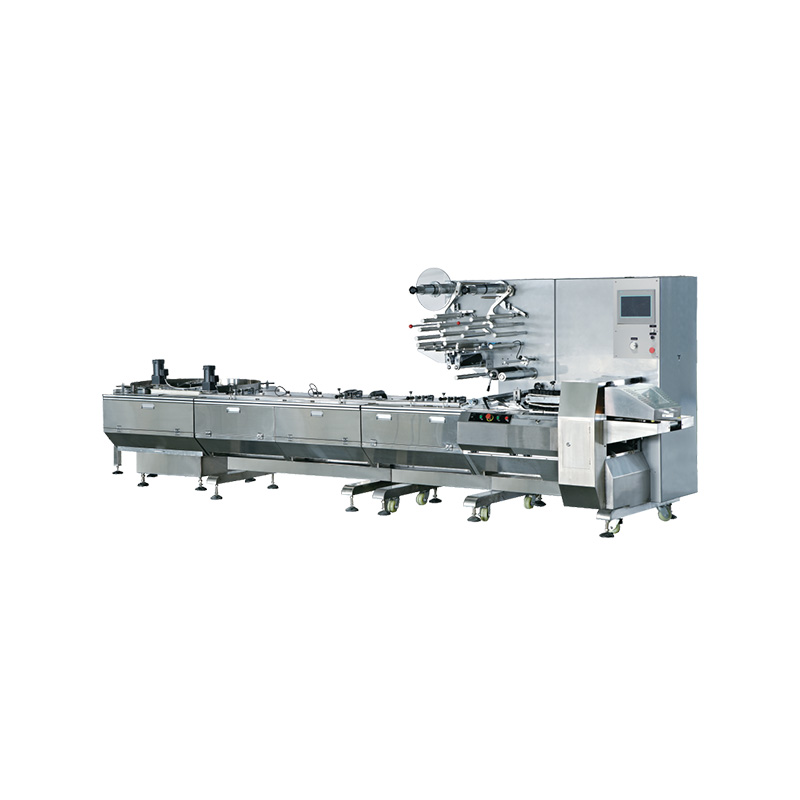

Additionally, consider the volume of production. High-output facilities may benefit from automated solutions that can operate continuously and efficiently. Equipment like a sweet wrapping machine can help maintain high production speeds while ensuring that each gummy is wrapped securely. Conversely, smaller operations might opt for more versatile equipment that allows for quick changeovers between different products without significant downtime.

Flexibility and Versatility

In an ever-evolving market, flexibility is key. Consumer preferences change rapidly, and manufacturers need to be able to adapt to new trends. The gummy packaging equipment you choose should allow for easy adjustments to accommodate different packaging formats and product sizes. A versatile lollipop packing machine, for instance, can often be repurposed for gummy packaging, providing manufacturers with the flexibility to expand their product lines without needing to invest in entirely new machinery.

Furthermore, consider the ability of the packaging equipment to handle various types of materials. The use of biodegradable or recyclable materials is on the rise, and being able to switch between different packaging types can help a company stay aligned with consumer expectations and sustainability goals.

Efficiency and Speed

Efficiency is another critical factor when selecting gummy packaging equipment. The speed at which your packaging line operates directly affects your overall productivity. A sweet wrapping machine designed for high-speed operation can significantly reduce the time taken to package each unit. This is especially important during peak production times or seasonal spikes in demand.

However, speed should not come at the expense of quality. High-quality gummy packaging equipment should ensure that every piece is wrapped correctly, preventing issues such as unwrapped candies or damaged packaging. The investment in equipment that balances speed and quality can result in long-cost savings by minimizing waste and reducing the need for rework.

Quality Control Features

Quality control is paramount in the food industry, and the packaging process plays a vital role in maintaining the integrity of gummy products. Look for gummy packaging equipment that offers built-in quality control features. This may include systems for checking seal integrity, fill levels, and even vision systems that can detect improperly wrapped products. Ensuring that each gummy is packaged correctly not only preserves freshness but also enhances customer satisfaction.

In addition to automated quality checks, consider equipment that allows for easy monitoring and adjustment. Many modern sweet wrapping machines are equipped with user-friendly interfaces that provide real-time data on production metrics. This level of oversight allows operators to make immediate adjustments, ensuring that the packaging process runs smoothly.

Safety and Hygiene Standards

Safety and hygiene are critical considerations in the confectionery industry. The equipment used in the packaging process must comply with food safety regulations to prevent contamination and ensure consumer safety. Look for gummy packaging equipment that is designed with hygiene in mind, featuring materials that are easy to clean and maintain.

Additionally, equipment that minimizes human contact during the packaging process can significantly reduce the risk of contamination. Automation plays a key role here; the use of a lollipop packing machine or similar automated systems can help ensure that the packaging environment remains sanitary, which is especially important for gummy candies that are often consumed without further cooking or preparation.

Selecting the right gummy packaging equipment is a multifaceted process that requires careful consideration of various factors. From understanding the unique needs of your products to ensuring efficiency and maintaining quality, every aspect plays a vital role in the success of your production line.

Related Product

Haven’t Found The Products You Want?

Quick Links

Contact information

postmaster@zjrczn.com

postmaster@zjrczn.com +86-13586059889

+86-13586059889 Building 40, Zone B, Feiyue Science and Technology Park, Airport Road, Jiaojiang District, Taizhou City, Zhejiang Province

Building 40, Zone B, Feiyue Science and Technology Park, Airport Road, Jiaojiang District, Taizhou City, Zhejiang Province

contact us

English

English