The Impact of Vertical Packaging Machines on the Food and Beverage Industry

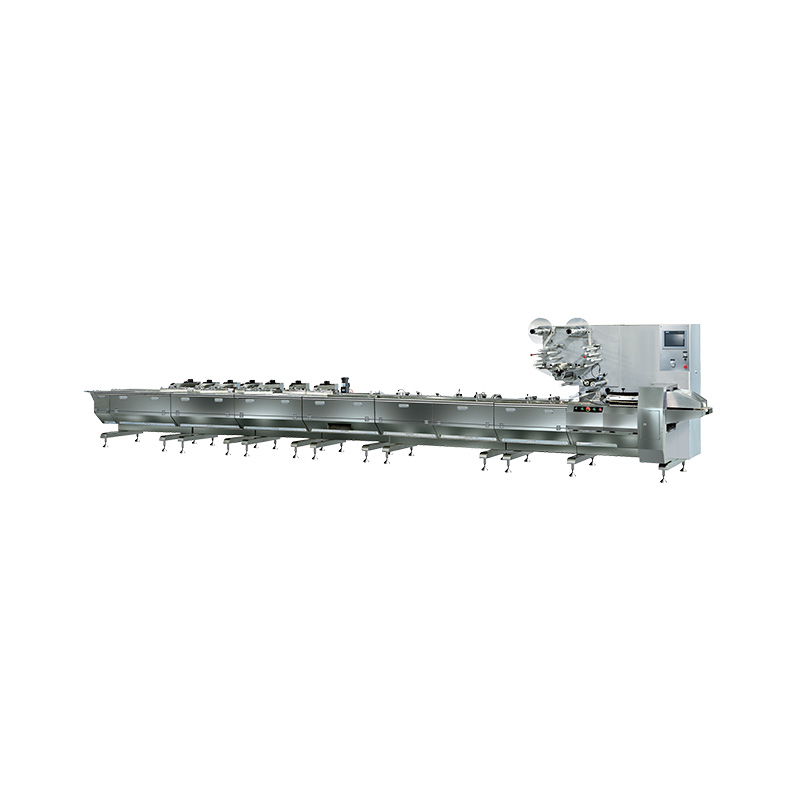

Custom OEM Vertical Packaging Shrink Wrap Filling Machine Maker

The food and beverage industry is a dynamic sector that is constantly evolving to meet the demands of a growing global population. One of the key innovations that have significantly impacted this industry is the vertical packaging machine. These machines have revolutionized the way products are packaged, ensuring efficiency, hygiene, and cost-effectiveness. In this article, we will explore the impact of Custom vertical packaging machines on the food and beverage industry, highlighting their benefits and challenges.

Vertical packaging machines have emerged as a critical component in the production lines of food and beverage companies. These machines are designed to package products in a vertical orientation, which allows for a more compact and space-efficient packaging format. The packaging machine's ability to handle a wide range of products, from liquids to solids, has made it an indispensable tool in the industry.

One of the significant impacts of vertical packaging machines on the food and beverage industry is the increase in efficiency and speed of packaging processes. Machines can operate at high speeds, packaging hundreds of units per minute, which is crucial for meeting the high demand in the food and beverage sector. This speed not only reduces production time but also allows companies to scale up their operations without a proportional increase in labor costs.

The vertical packaging machine plays a vital role in maintaining hygiene and safety standards within the food and beverage industry. These machines are designed with sanitation in mind, featuring easy-to-clean surfaces and components that reduce the risk of contamination. The closed nature of machines also helps to protect the product from external contaminants, ensuring that the final product is safe for consumption.

Vertical packaging machines offer a high degree of customization and flexibility, allowing companies to package a wide variety of products. This flexibility is particularly important in the food and beverage industry, where product diversity is the norm. The ability to quickly changeover between different packaging formats without significant downtime is a key advantage of machines.

The impact of OEM Vertical Shrink Wrap Machines on sustainability in the food and beverage industry cannot be overlooked. By using less packaging material, packaging machines contribute to reduced waste and a smaller environmental footprint. Furthermore, the energy efficiency of these machines compared to traditional packaging methods also helps to reduce the carbon emissions associated with packaging processes.

Despite the numerous benefits, vertical packaging machines also present some challenges and limitations. One of the main issues is the initial investment cost, which can be high for smaller food and beverage companies. Additionally, the complexity of these machines may require specialized maintenance and repair services, adding to the operational costs.

The food and beverage industry is constantly adapting to new trends, such as the demand for organic, gluten-free, and allergen-free products. Vertical packaging machines must be able to accommodate these trends by providing suitable packaging solutions that meet the specific needs of these niche markets. The adaptability of machines to these changing demands is crucial for the continued success of the food and beverage industry.

As technology continues to advance, the future of vertical packaging machines looks promising. We can expect to see more intelligence, networking capabilities, and integration with other production systems, which will further improve their efficiency and effectiveness. The development of new materials and packaging techniques will also allow machines to meet the evolving needs of the food and beverage industry.

In conclusion, the impact of Vertical Filling Machine Makers on the food and beverage industry has been profound. They have not only improved the efficiency and speed of packaging processes but also contributed to hygiene, safety, and cost-effectiveness. While challenges exist, the benefits of machines are clear, and their continued development and adoption will undoubtedly shape the future of the food and beverage industry. As companies continue to innovate and adapt to the changing landscape, vertical packaging machines will remain a critical component in the quest for excellence in food and beverage packaging.

English

English