The Benefits of Using Food Production Machines for Consistency and Quality

As consumer expectations rise, the demand for uniformity in taste, texture, and presentation has never been greater. To meet these challenges, food production machines have become indispensable tools for manufacturers. These machines streamline operations, enhance product quality, and ensure that bakery products manufacturing machinery operates at peak efficiency.

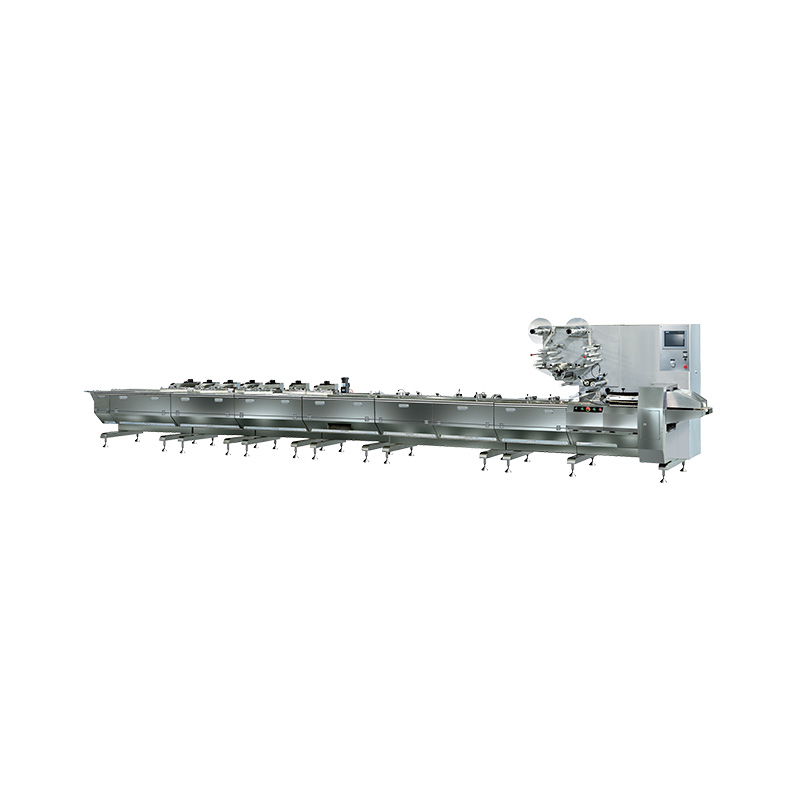

Food production machines encompass a wide array of equipment designed to automate various aspects of food processing, from mixing and baking to packaging. By incorporating food automatic machines into production lines, manufacturers can significantly improve their workflow and product output. These machines are designed to handle repetitive tasks with precision, reducing the variability that often comes with manual processes.

One of the primary benefits of using food production machines is the standardization of recipes. With automated systems, each ingredient is measured and mixed according to predetermined specifications, ensuring that every batch of product meets the same quality standards. This level of consistency is crucial, especially for bakery products manufacturing machinery, where even minor variations in ingredient ratios can cause significant differences in taste and texture.

Quality control is a vital aspect of food production, and food production machines play a key role in ensuring that quality standards are met throughout the manufacturing process. Advanced sensors and monitoring systems integrated into food automatic machines provide real-time data on various parameters, such as temperature, humidity, and mixing speed. This data allows manufacturers to make adjustments on-the-fly, preventing quality issues before they arise.

For example, in the context of bakery products manufacturing machinery, ovens equipped with precise temperature control can prevent over-baking or under-baking, which are common pitfalls in traditional baking processes. By ensuring that each product is baked under good conditions, manufacturers can deliver consistently high-quality baked goods that meet consumer expectations.

The implementation of food production machines also translates to significant efficiency gains. Automated systems can operate continuously with minimal downtime, improving output and reducing labor costs. In an industry where timing is crucial, the ability to produce large quantities of product quickly and efficiently can provide a competitive edge.

Moreover, food automatic machines can work at a pace that surpasses human capabilities. For instance, a high-speed mixing machine can blend ingredients far faster than manual mixing, allowing production lines to maintain high throughput. This increased productivity not only meets consumer demand but also helps manufacturers scale their operations without compromising quality.

Food safety is a top priority for manufacturers, and the use of food production machines can enhance safety protocols throughout the production process. Automated systems minimize human interaction with food, reducing the risk of contamination. Additionally, these machines often come with built-in cleaning and sanitizing features, ensuring that equipment is maintained in a hygienic condition.

In the bakery sector, for instance, food production machines can be designed to meet stringent food safety standards, with features that comply with regulations set by health authorities. This commitment to safety is crucial in building consumer trust and maintaining a brand's reputation in the market.

Another significant advantage of food production machines is their adaptability. As consumer preferences change and new trends emerge, manufacturers must be able to pivot quickly to meet these demands. Food automatic machines can often be reprogrammed or adjusted to accommodate different recipes or production methods, allowing for greater flexibility in product offerings.

For example, bakery products manufacturing machinery can be configured to produce gluten-free or organic products, tapping into the growing market for health-conscious consumers. This ability to innovate while maintaining consistency in quality makes automated systems invaluable for modern food production.

While the initial investment in food production machines may be substantial, the long-cost savings can be significant. By reducing labor costs, minimizing waste, and enhancing product quality, manufacturers can achieve a quicker return on investment. The efficiency gained from automated systems often guides to lower production costs per unit, allowing businesses to remain competitive in a crowded marketplace.

English

English