How Hard Candy Wrapping Machines Improve Product Quality and Presentation

As the market for hard candies continues to grow, manufacturers are increasingly turning to advanced technology to ensure their products meet high standards. One significant innovation is the hard candy wrapping machine, which not only enhances the wrapping process but also plays a vital role in improving the overall quality and presentation of the final product.

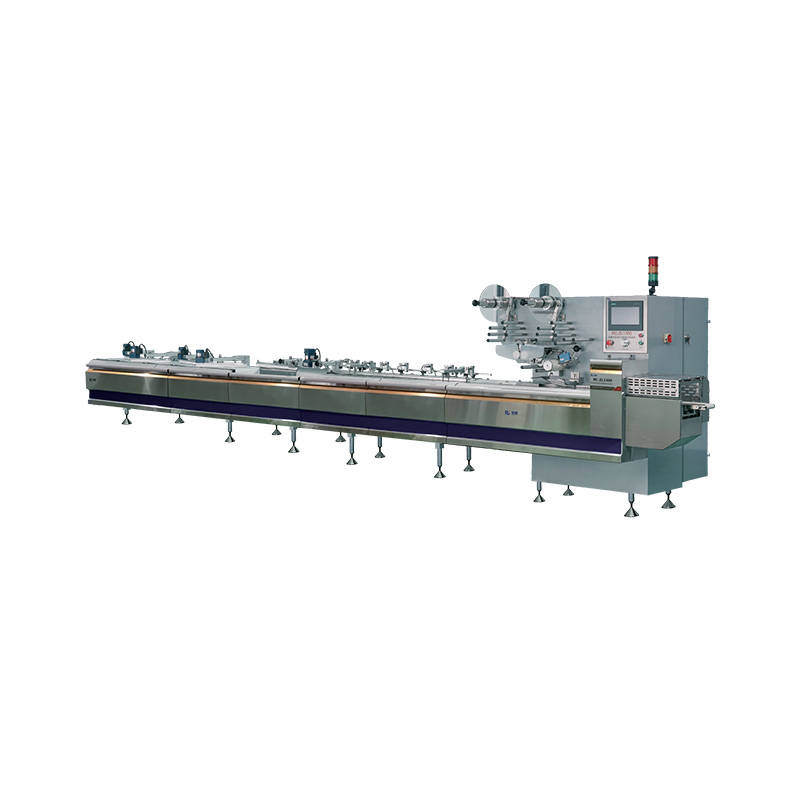

The primary purpose of a hard candy wrapping machine is to provide a consistent, efficient, and high-quality packaging solution. This machinery is designed to handle various candy types with precision, ensuring that each piece is wrapped securely and attractively. By automating the wrapping process, manufacturers can significantly reduce the risk of human error, which can cause inconsistent packaging and potential product damage. With a candy bar packaging machine, producers can also streamline their operations, increasing throughput while maintaining quality.

One of the standout features of a hard candy wrapping machine is its ability to wrap candies in a variety of styles. This flexibility is essential for brands aiming to differentiate their products on store shelves. Whether it’s a twist wrap, flow wrap, or a pillow pack, these machines can accommodate diverse packaging needs. The ability to switch between different wrapping styles quickly allows manufacturers to respond to market trends and consumer preferences without the need for extensive downtime.

Moreover, the wrapping process is critical for maintaining the freshness and integrity of hard candies. A well-designed hard candy wrapping machine effectively seals each piece, protecting it from moisture, air, and contaminants. This preservation is essential for ensuring that the candies retain their flavor, texture, and overall quality. In an industry where consumer satisfaction hinges on product experience, the importance of effective packaging cannot be overstated.

In addition to the functional benefits, the presentation of hard candies plays a significant role in attracting consumers. The visual appeal of a product can greatly influence purchasing decisions, especially in the confectionery market. A candy bar packaging machine is designed to create eye-catching presentations that showcase the product beautifully. With the ability to print vibrant graphics and logos directly onto the packaging, manufacturers can enhance their brand visibility and create a strong identity in a crowded marketplace.

The integration of modern technology into hard candy wrapping machines also enhances the efficiency of the packaging process. Many of these machines are equipped with advanced features such as programmable settings, touch screen controls, and real-time monitoring. This technological sophistication enables operators to adjust settings easily, ensuring good performance and minimal downtime. Additionally, data collected from the machines can provide insights into production efficiency, helping manufacturers identify areas for improvement.

Sustainability is another growing concern in the confectionery industry. Consumers are increasingly seeking products that align with their environmental values. Many hard candy wrapping machines are designed to work with eco-friendly materials, allowing manufacturers to minimize their ecological footprint. By choosing sustainable packaging solutions, brands can appeal to environmentally conscious consumers while maintaining high standards of quality and presentation.

Furthermore, a hard candy wrapping machine can contribute to safety and hygiene in the manufacturing process. Automated systems reduce the need for human handling, which minimizes the risk of contamination. In an industry where cleanliness is paramount, this feature can significantly enhance the safety of the final product. Brands that prioritize food safety often enjoy a competitive advantage, as consumers are more likely to choose products they trust.

In comparison, chocolate bar packing machines also play a crucial role in the confectionery sector, but they serve different packaging requirements. While both types of machines aim to improve quality and presentation, the specific needs of chocolate, such as temperature control and protection from melting, demand unique features. By investing in specialized machines for each product type, manufacturers can optimize their production lines and ensure that each candy product is packaged in a manner that preserves its quality and appeal.

The impact of hard candy wrapping machines on product quality and presentation is significant. These machines not only streamline the packaging process but also ensure that each piece of candy is wrapped securely and attractively. With the ability to accommodate various wrapping styles, maintain product freshness, and enhance visual appeal, a hard candy wrapping machine is an invaluable asset for manufacturers.

English

English