How Hard Candy Packaging Machines Ensure Product Integrity and Quality

In the confectionery industry, maintaining product integrity and quality is paramount, particularly for hard candies, which are popular among consumers for their taste and texture. As competition grows and consumer expectations rise, manufacturers must adopt advanced technologies to ensure that their products remain fresh, flavorful, and appealing.

One of the primary functions of a hard candy packaging machine is to create airtight seals that shield candies from moisture, air, and contaminants. Hard candies are especially sensitive to these elements, which can cause them to lose their desired texture and flavor over time. By employing an individual candy wrapping machine, manufacturers can ensure that each piece is individually wrapped, providing an additional layer of protection. This not only helps preserve the product's integrity but also extends its shelf life, allowing companies to reduce waste and meet consumer demand more effectively.

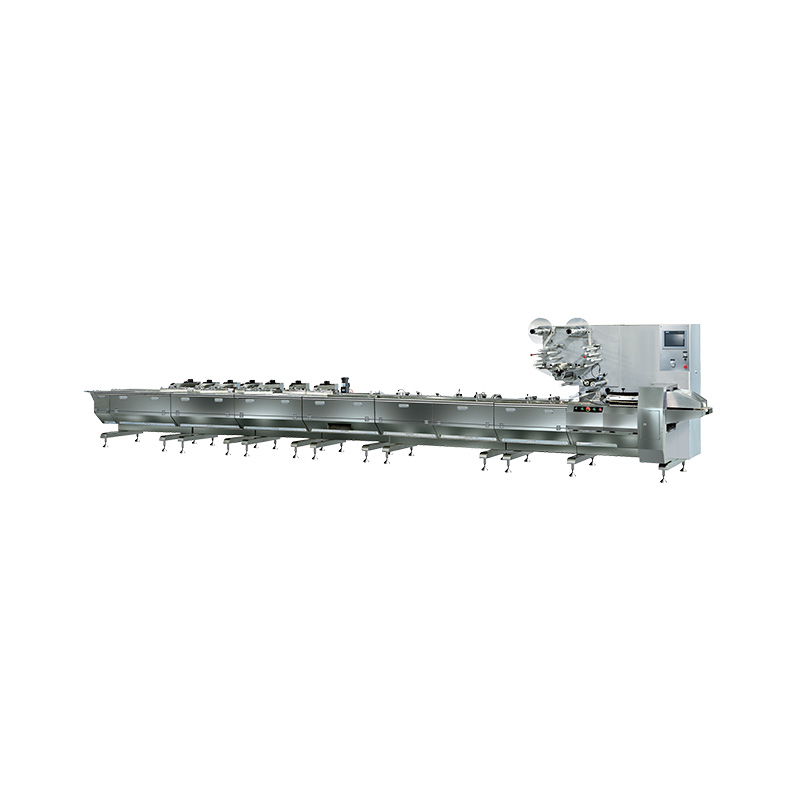

The efficiency and speed of hard candy packaging machines are also vital in maintaining quality. In a high-demand market, the ability to package large volumes of candy quickly without sacrificing quality is essential. Modern hard candy packaging machines are designed to operate at impressive speeds, wrapping thousands of candies per hour. This efficiency is crucial during peak production times, allowing manufacturers to keep pace with consumer demand while maintaining high standards of quality.

Additionally, the versatility of these machines means they can accommodate a wide range of candy sizes and shapes. For example, an individual candy wrapping machine can be easily adjusted to wrap both small and large candies, ensuring that manufacturers can adapt to changing market trends without needing to invest in new equipment. This flexibility not only saves time but also reduces production costs, making it a worthwhile investment for businesses looking to optimize their operations.

Quality control is another critical aspect of the packaging process. Hard candy packaging machines are often equipped with advanced monitoring systems that ensure each piece is wrapped correctly. This includes checks for proper sealing and alignment, which can help prevent issues such as unwrapped candies or damaged packaging. By incorporating quality control measures directly into the packaging process, manufacturers can significantly reduce the risk of defects, thereby enhancing consumer satisfaction.

Furthermore, the choice of packaging materials is essential in maintaining the integrity of hard candies. Many modern hard candy packaging machines are compatible with a variety of materials, including foil, plastic, and biodegradable options. The ability to select the right packaging material for each product can significantly impact freshness and appeal. For example, foil wrappers can provide outstanding barrier properties, protecting candies from light and moisture, while still allowing for attractive designs that draw consumers in.

In contrast, soft candies require different packaging considerations, often addressed by a soft candy wrapping machine. These machines are specifically designed to handle the unique properties of soft candies, which may be more susceptible to sticking and deformation. While hard candy packaging machines focus on airtight seals, soft candy wrappers often need to account for flexibility and cushioning. By utilizing the appropriate machinery for each candy type, manufacturers can ensure that all products maintain their quality and integrity throughout the packaging process.

Sustainability is also a growing concern in the confectionery industry. Consumers are increasingly looking for brands that prioritize eco-friendly practices, and packaging is a significant factor in this decision. Hard candy packaging machines that work with sustainable materials can help manufacturers meet these consumer demands. Many machines are now designed to handle biodegradable and recyclable packaging materials, allowing companies to reduce their environmental impact while still delivering high-quality products.

The automation of the packaging process through the use of hard candy packaging machines also reduces the need for manual handling, which can introduce contaminants. By minimizing human contact with the product, manufacturers can further ensure the hygiene and safety of their candies. This is particularly important in a market where food safety regulations are stringent, and consumers are more health-conscious than ever.

Hard candy packaging machines are essential tools for ensuring product integrity and quality in the confectionery industry. From protecting candies from external elements with airtight seals to enhancing efficiency and flexibility, these machines play a crucial role in modern production lines.

English

English