How a Manual Candy Wrapping Machine Can Benefit Small-Scale Producers

A manual candy wrapping machine is designed to help small-scale candy producers efficiently wrap their products without the need for extensive automation. Unlike high-speed industrial machines, this type of equipment allows for more control over the wrapping process, making it ideal for artisanal and small-batch production. These machines are typically compact, making them suitable for small production spaces, and they can handle various types of candies, including chocolate bars, gummies, and hard candies.

One of the primary advantages of a manual candy wrapping machine is its cost-effectiveness. For small-scale producers, investing in high-speed, fully automated candy bar wrapping machines may not be feasible due to the associated costs and maintenance requirements. In contrast, a small candy wrapping machine offers an affordable alternative that can still significantly streamline operations.

With lower upfront costs and minimal operating expenses, a manual candy wrapping machine allows small producers to allocate their budgets more efficiently. This can be particularly beneficial for businesses just starting or those looking to expand their product lines without incurring substantial debt.

Another key benefit of using a manual candy wrapping machine is its flexibility. These machines often come with adjustable settings that allow producers to customize the wrapping process according to their specific needs. Whether you are wrapping irregularly shaped candies or different sizes of chocolate bars, a small candy wrapping machine can accommodate various product dimensions and shapes.

This adaptability is essential for small producers who may experiment with new recipes or limited-edition flavors. The ability to quickly adjust the machine settings ensures that your wrapping process can keep up with the creative demands of your product line, maintaining a fresh and appealing offering for your customers.

Packaging plays a critical role in consumer perception, and a well-wrapped product can significantly enhance its appeal. A manual candy wrapping machine allows producers to achieve a professional finish that reflects the quality of their candies. The consistent wrapping ensures that each piece is presented attractively, which can attract customers on retail shelves or at events.

Additionally, with the option to use custom printed wrappers, small-scale producers can showcase their brand identity through their packaging. Eye-catching designs and logos can make a product stand out, encouraging consumers to choose your candy over competitors. The professional look of well-wrapped candy can also foster trust and credibility with potential buyers, particularly in crowded markets.

While manual candy wrapping machines require human operation, they can still significantly improve efficiency compared to hand-wrapping. By mechanizing the process, producers can wrap candies more quickly and consistently, saving valuable time during production. This efficiency is particularly crucial during peak seasons or special events when demand for products may surge.

Furthermore, a manual machine can help reduce labor fatigue. Continuous hand-wrapping can cause tired hands and decreased productivity over time. By using a small candy wrapping machine, workers can maintain a steady pace without compromising quality, allowing them to focus on other critical aspects of production.

In the food industry, packaging also plays a vital role in maintaining hygiene and safety standards. A manual candy wrapping machine helps ensure that candies are wrapped in a clean and controlled environment, reducing the risk of contamination. Properly sealed wrappers protect the product from external factors such as dust, moisture, and pests, which is crucial for preserving flavor and quality.

Additionally, many small-scale producers are now focused on sustainability. Manual wrapping machines can be used with eco-friendly materials, allowing producers to align their packaging practices with consumer preferences for environmentally conscious products. This alignment can further enhance brand reputation and appeal.

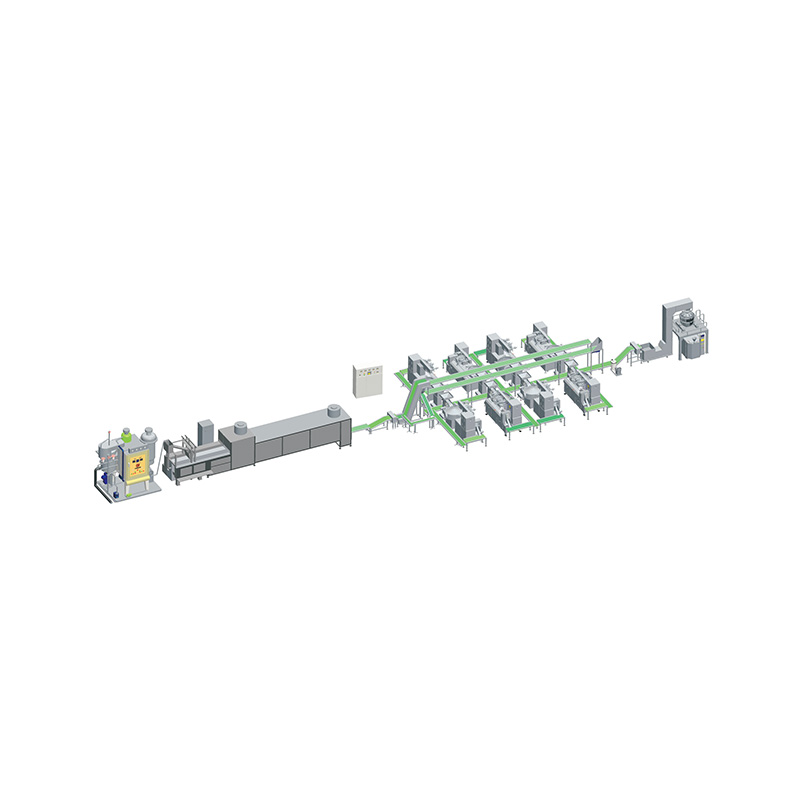

The toffee packing machine is an invaluable asset in the confectionery production process. Its ability to package toffees efficiently while preserving their quality makes it essential for small and large producers alike. By integrating with a sweet packing machine and a chocolate wrapper machine, manufacturers can create a streamlined and versatile production line that accommodates a wide variety of confectionery products.

English

English