Exploring the Advantages of Using a Bread Wrapping Machine in Bakeries

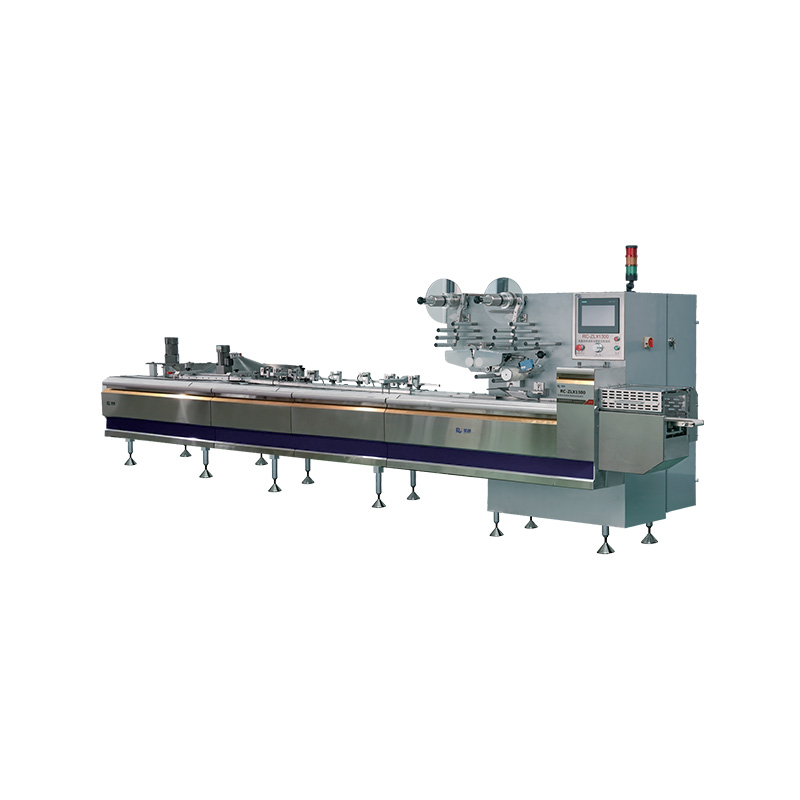

In the bustling environment of a bakery, efficiency is key. The bakery product machine, specifically the bread wrapping machine, plays a crucial role in maintaining the pace of production. By automating the wrapping process, bakeries can save time and labor, allowing staff to focus on other aspects of the business, such as customer service and product quality. The bread wrapping machine's efficiency is not just about speed; it also ensures consistency in packaging, which is essential for maintaining a professional image and meeting consumer expectations.

One of the primary advantages of an automatic bread packing machine is its ability to reduce waste. By precisely cutting and wrapping bread to the desired size and shape, bakeries can minimize the amount of bread that goes to waste. This not only benefits the bottom line but also aligns with sustainability goals, as less food is discarded. The environmental impact of food waste is a growing concern, and by using a bread wrapping machine, bakeries can take a proactive step towards reducing their carbon footprint.

The hygiene standards in the food industry are stringent, and the use of a bread wrapping machine helps maintain these standards. An automatic bread packing machine reduces human contact with the bread, minimizing the risk of contamination. This is particularly important in an era where consumers are increasingly aware of food safety and hygiene. The machines are designed to be easy to clean and maintain, further ensuring that the bread remains uncontaminated throughout the packaging process.

For bakery owners looking to expand their product line, the versatility of a bread wrapping machine is a significant advantage. These machines can be used to wrap a variety of bread types, from traditional loaves to artisanal breads with unique shapes. This flexibility allows bakeries to experiment with new products without the need for additional equipment. The ability to quickly adapt to different bread types and sizes is a valuable asset in a competitive market where innovation is key.

The cost-effectiveness of a bread wrapping machine cannot be overlooked. While the initial investment may seem substantial, the long-savings in labor and reduced waste can quickly offset the cost. Additionally, the increased efficiency can cause higher production volumes, which can result in higher profits. For small and medium-sized bakeries, the affordability of some bread wrapping machines makes them an accessible investment that can contribute to the growth of the business.

In the age of social media, the presentation of bakery products is more important than ever. A well-packaged loaf of bread can be just as enticing as its taste. The bread wrapping machine allows for customized packaging, enabling bakeries to create a unique brand identity. From the choice of wrapping material to the design of the label, the automatic bread packing machine offers endless possibilities for customization. This not only helps in differentiating the bakery's products in the market but also adds to the overall customer experience.

The convenience offered by a bread wrapping machine is another significant advantage. The machines are designed to be user-friendly, with intuitive controls that make operation easy even for those without extensive technical knowledge. This means that bakery staff can be trained quickly, reducing downtime and ensuring that the packaging process runs smoothly. The machines are also designed to minimize downtime due to maintenance, ensuring that the bakery's production line remains operational.

The advantages of using a bread wrapping machine in bakeries are manifold. From enhancing efficiency and reducing waste to improving hygiene and offering customization options, these machines are a valuable asset for any bakery. The automatic bread packing machine is not just a tool for packaging; it is a strategic investment that can contribute to the growth and success of a bakery. As the bakery product machine continues to evolve, the role of the bread wrapping machine will remain central to the industry, ensuring that the art of bread making is preserved while meeting the demands of the modern consumer.

English

English