Product Search

Language

Exit Menu

Industry News

Home / News / Industry News / Choosing the Right Automated Packaging Equipment for Your Product Line

Author: RONGCHUANG

Date: 2024-10-29

Choosing the Right Automated Packaging Equipment for Your Product Line

Step in choosing the right automated packaging equipment is understanding the unique requirements of your product line. Every product, from food items to electronics, has distinct packaging needs that must be met to ensure product safety, shelf appeal, and consumer satisfaction. Machinery automation plays a pivotal role in achieving these goals, and the selection process should begin with a thorough analysis of your product's characteristics.

For instance, if your product line includes fragile items such as glassware or delicate electronics, you'll need machinery automation that can handle these items with care. On the other hand, if you're packaging bulk items like cereal or pet food, you'll require a different type of automated packaging equipment that can handle heavy loads and ensure the product packaging bags are filled accurately and sealed properly.

Once you've identified the specific needs of your product line, it's time to consider the various types of automated packaging equipment available. Machinery automation can range from simple, semi-automatic machines to fully automated systems that can handle multiple steps of the packaging process. Each type of equipment has its own set of benefits and drawbacks, and choice will depend on your production volume, budget, and available space.

For small to medium-sized businesses, semi-automatic machinery automation may be cost-effective option. These machines require some manual input but can still significantly speed up the packaging process. For example, a semi-automatic machine might require an operator to place the product on the packaging line, but the machine will then automatically fill the product packaging bags, seal them, and prepare them for labeling or boxing.

Larger companies with high production volumes may benefit from fully automated machinery automation. These systems can handle every aspect of the packaging process, from filling and sealing to labeling and boxing. While they are more expensive upfront, they can save time and labor costs in the long run. Additionally, fully automated machinery automation can help ensure consistency in product packaging bags, which is crucial for maintaining a professional brand image.

Another important factor to consider when choosing automated packaging equipment is the machine's flexibility. machinery automation should be able to adapt to different product sizes, shapes, and packaging materials. This flexibility allows you to use the same equipment for multiple product lines, reducing the need for additional investment in machinery automation.

For example, if your product line includes both small bottles and large jars, you'll need machinery automation that can accommodate these different sizes. Similarly, if you plan to switch between different packaging materials, such as plastic and glass, you'll need a machine that can handle these variations without compromising the quality of the product packaging bags.

In addition to the machine's flexibility, you should also consider its ease of use and maintenance. automated packaging equipment should be user-friendly, with intuitive controls and a clear display screen. This will make it easier for your staff to operate the machine and minimize the risk of errors.

Maintenance is another crucial aspect to consider. Machinery automation that requires frequent and complex maintenance can be a drain on your resources and time. Look for machines that are designed for easy maintenance, with accessible parts and clear instructions for routine checks and repairs.

Finally, don't forget to consider the environmental impact of your automated packaging equipment. As more companies are becoming aware of the need for sustainable practices, machinery automation that minimizes waste and energy consumption is becoming increasingly important. Look for machines that are designed with energy efficiency in mind and that use materials that can be easily recycled or reused.

Choosing the right automated packaging equipment for your product line is a critical decision that can have a significant impact on your business's success. By considering factors such as the specific needs of your product line, the type of machinery automation available, the machine's flexibility, ease of use, maintenance requirements, and environmental impact, you can select equipment to meet your needs and ensure that your product packaging bags are consistently high-quality and appealing to your customers.

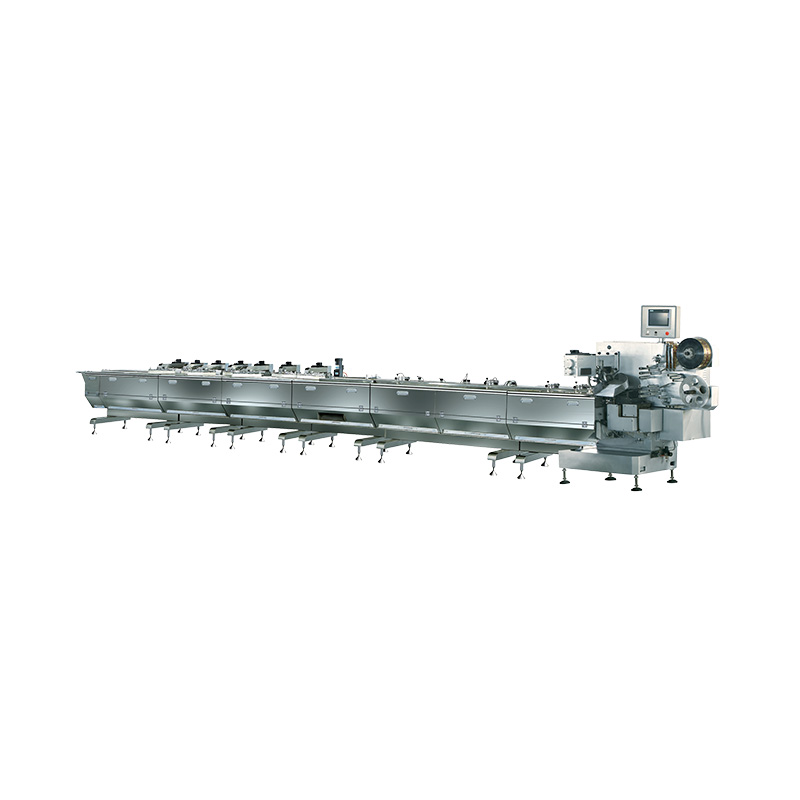

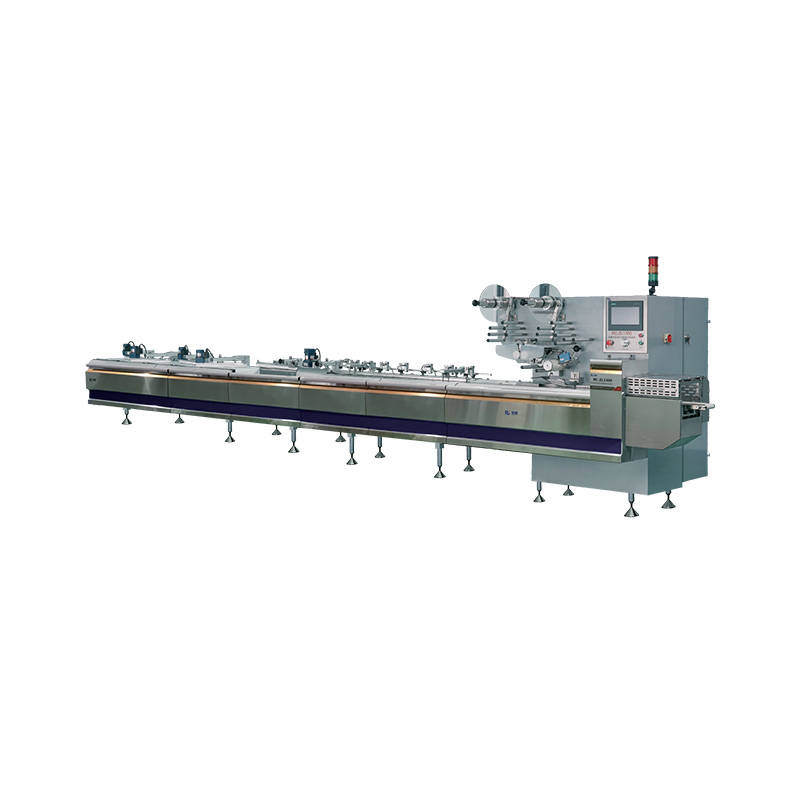

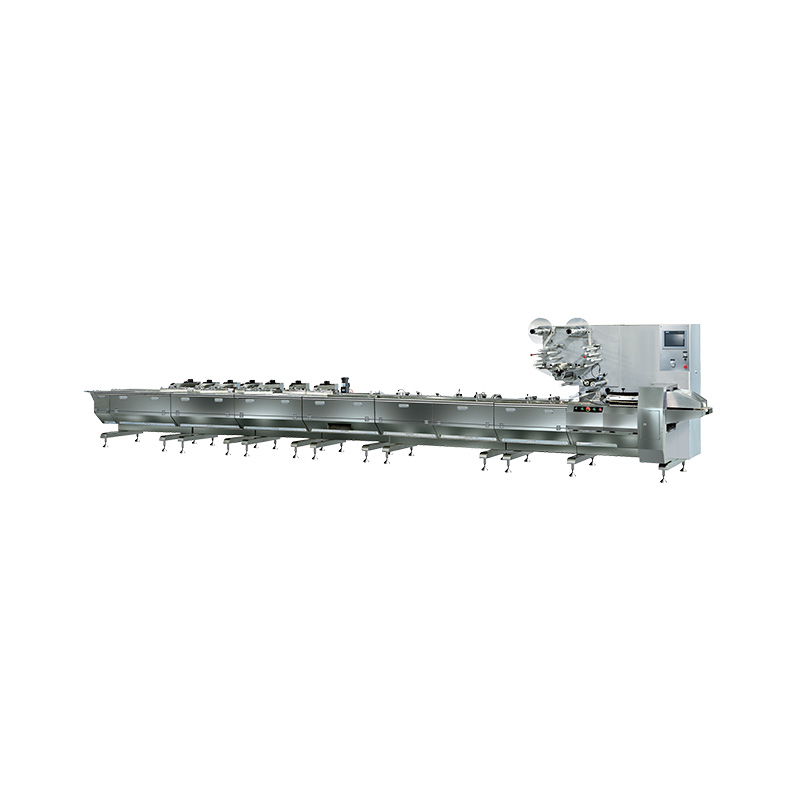

Related Product

Haven’t Found The Products You Want?

Quick Links

Contact information

postmaster@zjrczn.com

postmaster@zjrczn.com +86-13586059889

+86-13586059889 Building 40, Zone B, Feiyue Science and Technology Park, Airport Road, Jiaojiang District, Taizhou City, Zhejiang Province

Building 40, Zone B, Feiyue Science and Technology Park, Airport Road, Jiaojiang District, Taizhou City, Zhejiang Province

contact us

English

English